Basic information:

Sytec developed the bridge cornice panels technology in 1995. Currently more than 2500 bridges and overpasses in Poland have implemented this technology with great success. In recent years and with the background of past experiences, SYTEC bridge cornices are now used in other European countries. The cornices are made in polymer concrete, material of high physical and chemical resistance. Bridge cornice panels offers state of the art design, cost savings, corrosion resistance.

Advantages:

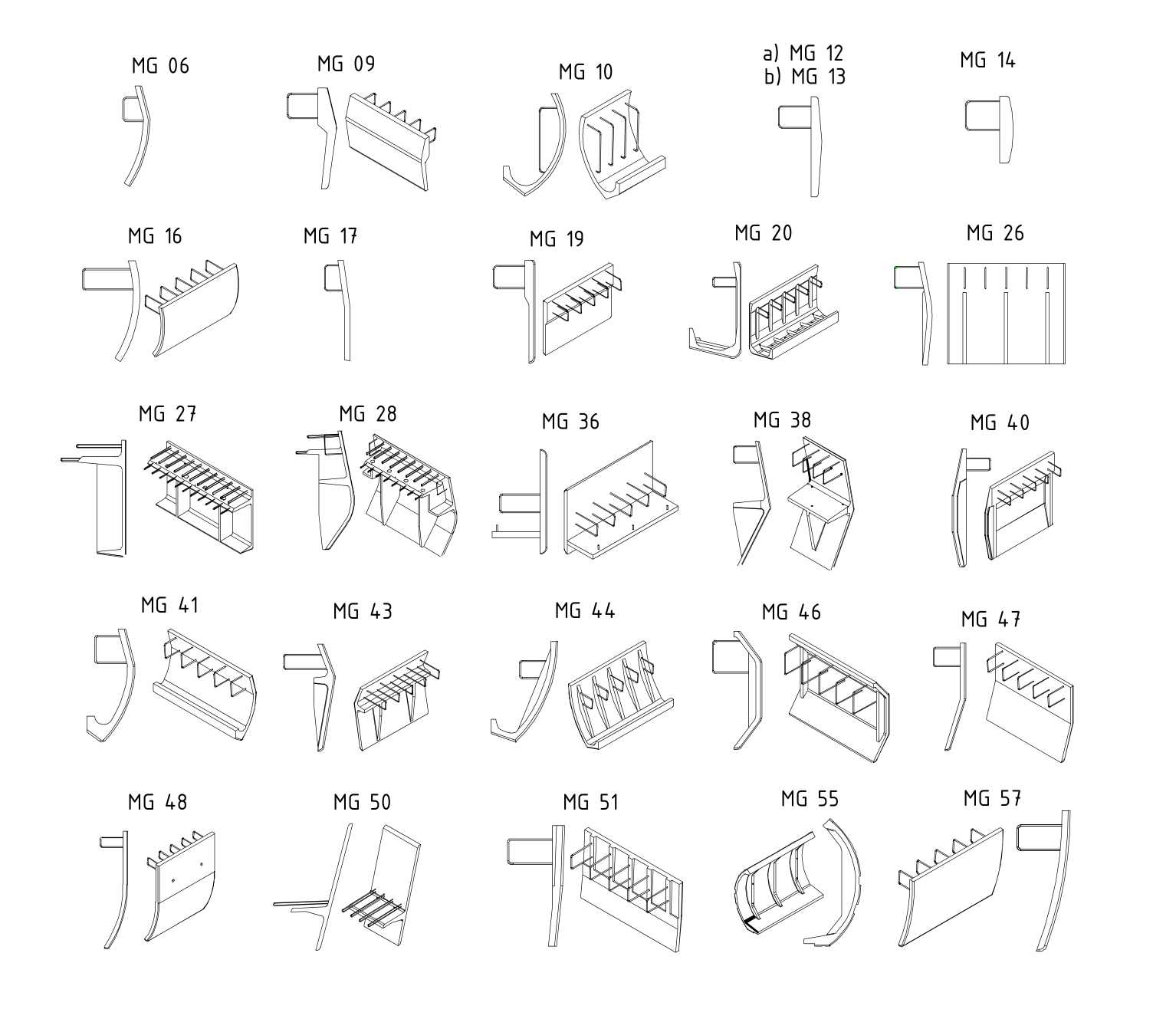

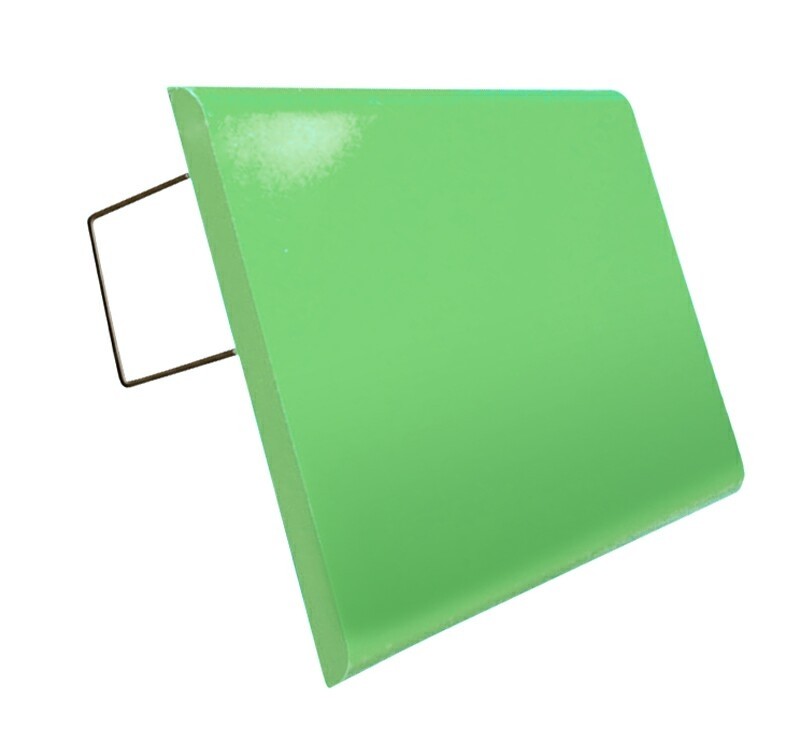

- Cornices panels are manufactured in different sizes and attractive shapes.

- Cornice panels provide a direct concrete framework when building the bridge deck and side walk infrastructure with evident economical savings.

- Polymer concrete cornice panels protect the bridge against chloride corrosion, carbonation and sulfate attack.

- The very low water absorption of the cornice panels ensures excellent frost resistance.

- Bridge cornices are lighter than traditional regular concrete reinforced panels reducing bridge dead load.

- Bridge cornices are permanently anchored to the bridge structure providing a long lasting service time.

- Cornice panels are offered in wide range of colors giving a nice appearance and unique identity to the bridge.

- The cornice panel innovation is widely used in both new and existing bridges or overpasses allowing a quick infrastructure protection and appearance improvement.

Intended purpose of the product:

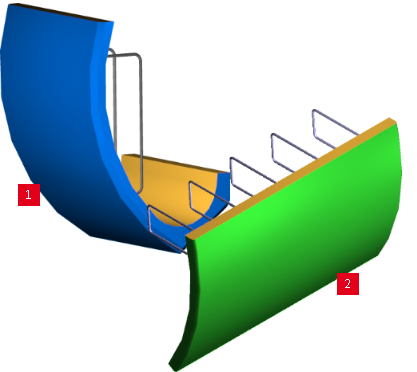

A bridge cornice precast unit is a bridge structure component constituting an external lining of a supporting structure of a bridge. It can be used as a permanent formwork. It is intended for protection of concrete, steel, and reinforced concrete bridge components against chemically active aqueous solutions.

Application scope:

A cornice precast unit can be used without any restrictions on road and railway structures.

Assembly methods:

There are two basic cornice installation methods.

- Cornices are fixed to the supporting structure with stirrups made of steel in accordance with Technical Specifications.

- In case of renovation of bridge structures, cornice boards can also be used and fixed to the supporting structure with bonded or expansion anchors.

| File name | File size | |

|---|---|---|

| Technical Data Sheet MG MGK | 448 KB | download |

| Leaflet MG | 9830 KB | download |